Who we are

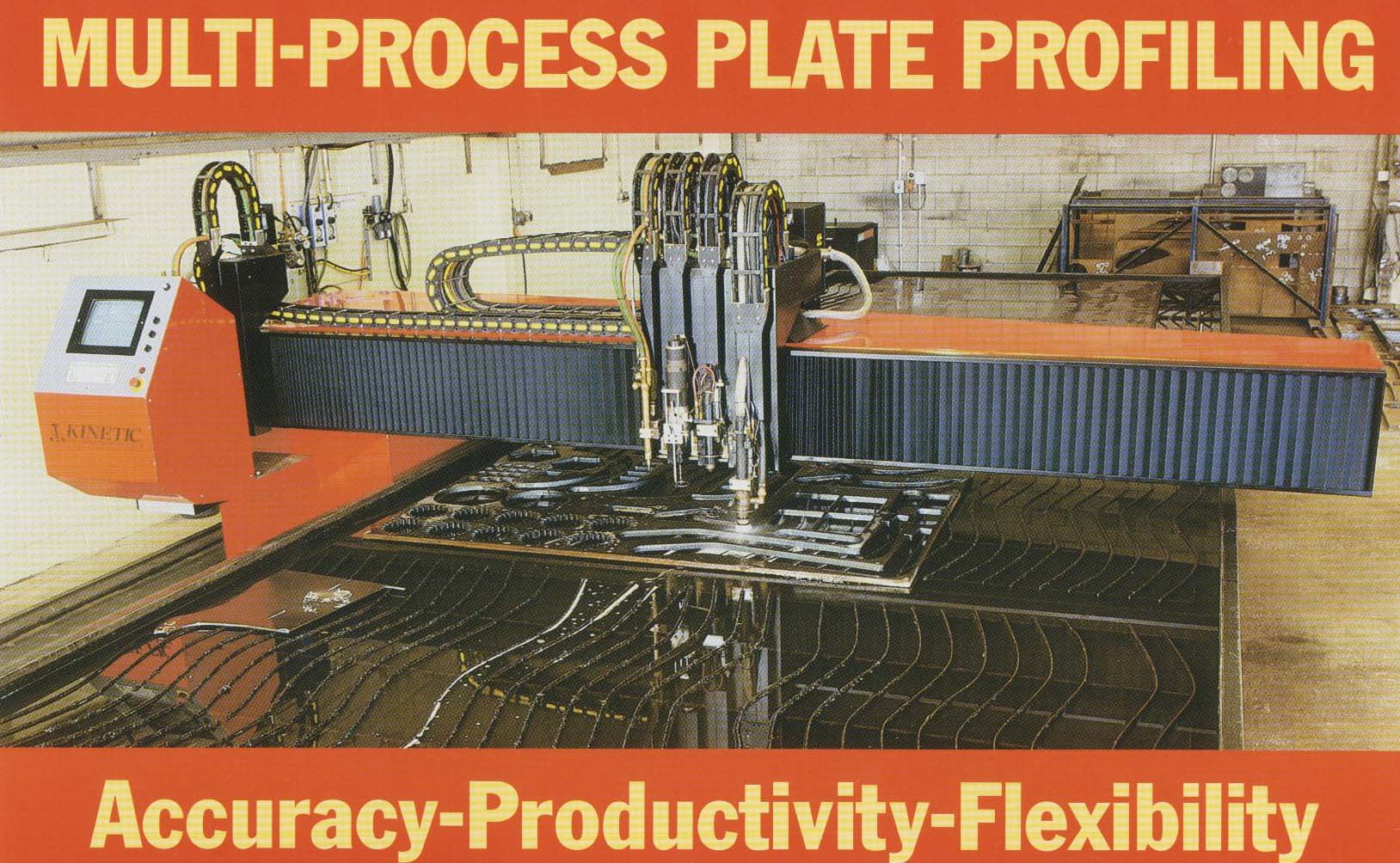

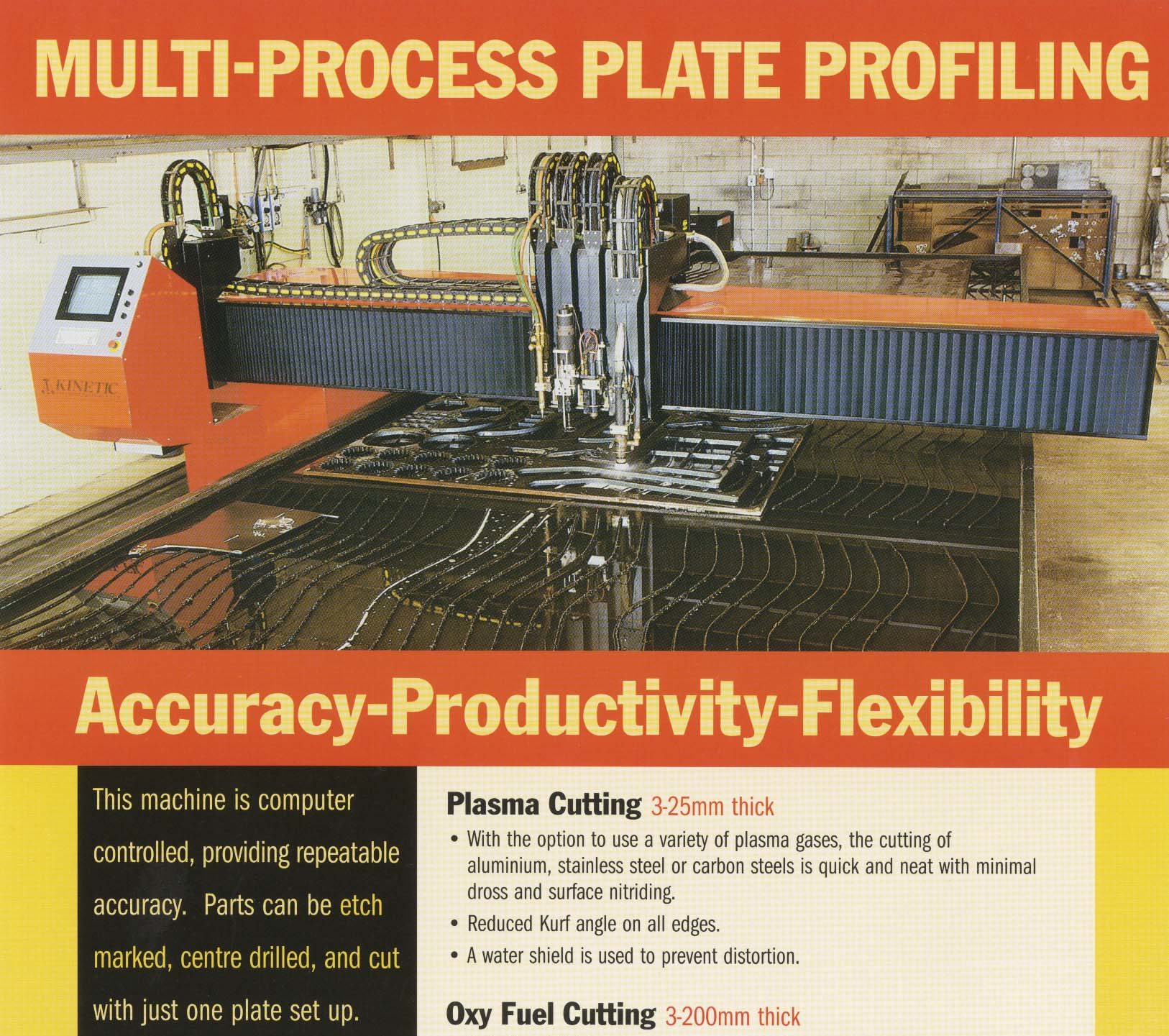

Marshall Profiling is a dedicated, stand alone cutting centre specialising in CNC Plate and Sheet Processing. We offer a full range of processing services across an extensive range of carbon, stainless and aluminium materials from 0.5mm up to 200mm thick.

For over 20 years we have consistently offered the shortest lead times in the market, and our people, processes and dedication, ensure we deliver on our promises. As result, our service and expertise continues to be respected and relied upon by our customers who demand speed, flexibility and reliability.

Originally founded by Peter Marshall in 1997 from our parent company JP Marshall Engineering, today Marshall Profiling is a second generation family owned and operated business with a large fully equipped workshop in Hamilton.

We pride ourselves on being large enough to tackle the big jobs but with the family values to still care about the little ones. This philosophy along with trained staff, customer dedication and up to date technology ensures we continue to maintain our reputation as a leader in our field.

Quality

It is Marshall Profiling’s mission to ensure that quality is not sacrificed and our customers are satisfied and remain satisfied with our work. Most importantly, we stand by everything we do! All work is undertaken and supervised by staff that are competent to undertake the work required. We demand the best from our staff and invest time and money in training them on aspects relating to quality assurance.

Safety

Eliminating or mitigating Health & Safety risks in our work so everyone gets home safely is an obligation everyone at Marshall Profiling shares and takes seriously.

Company History

1956

Marshall Profiling’s origins

Marshall Profiling's journey started with the original JP Marshall Engineering team, led by John Marshall.

1990s

Investment in technology

Our first CNC Plasma and Oxy-fuel cutting machines were purchased.

1997

Marshall Manufacturing is Born

Marshall Manufacturing is established as a separate company specialising in Plasma and Oxy-Fuel cutting.

2000

Expanding capacity

Expanding Plasma Cutting capacity to supply to the growing aluminium boat industry.

2004

First Press Brake

Marshall Profiling installs its first 400T CNC Press Brake

2006

Marshall Profiling established

Reflecting its position as specialist steel plate profilers, Marshall Manufacturing changes its name to Marshall Profiling.

2011

NZs most powerful Laser Cutting

Installation of the top of the line 6kW Trumpf Laser. NZ's most powerful laser cutter at the time.

2018

The growth continues

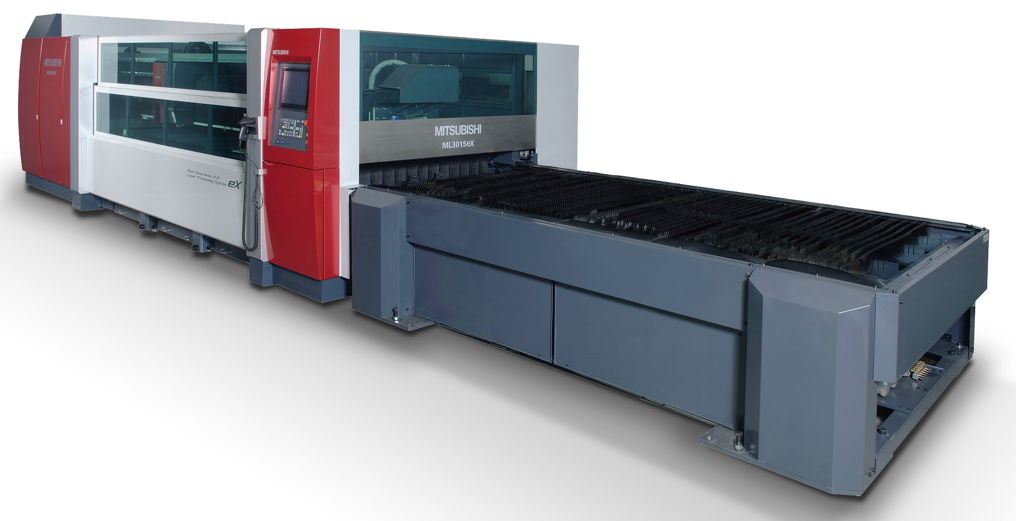

Extending Marshall Profiling's Laser cutting capacity with the installation of 4.5kW Mitsubishi Laser Cutter.

2019

The present day

Marshall Profiling now employees over 35 staff and operates more than 12 plate processing machines.