Oxy Fuel Cutting

| TABLE | 6300 x 3200 |

|---|---|

| Cut | |

| Carbon Steel | up to 200mm |

For straight, clean cutting of sections 20-200mm thick, the combination of a CNC Kinetic 3000 and the time proven process of Oxy Fuel cutting, enables Marshall Profiling to offer a full compliment of cutting services all at the one location.

With multi torch capabilities and plasma piercing for faster cut starts, this 100 year old cutting technology has been enhanced to modern gas cutting capability and is an essential part of our processing capabilities.

We also offer a range of part finishing and surface treatment processes including sand blasting, painting, galvanising, electroplating and rumbling and vibratory de-burring.

Contact us today, our large team of estimators and production facilitators are ready to help get your parts into production.

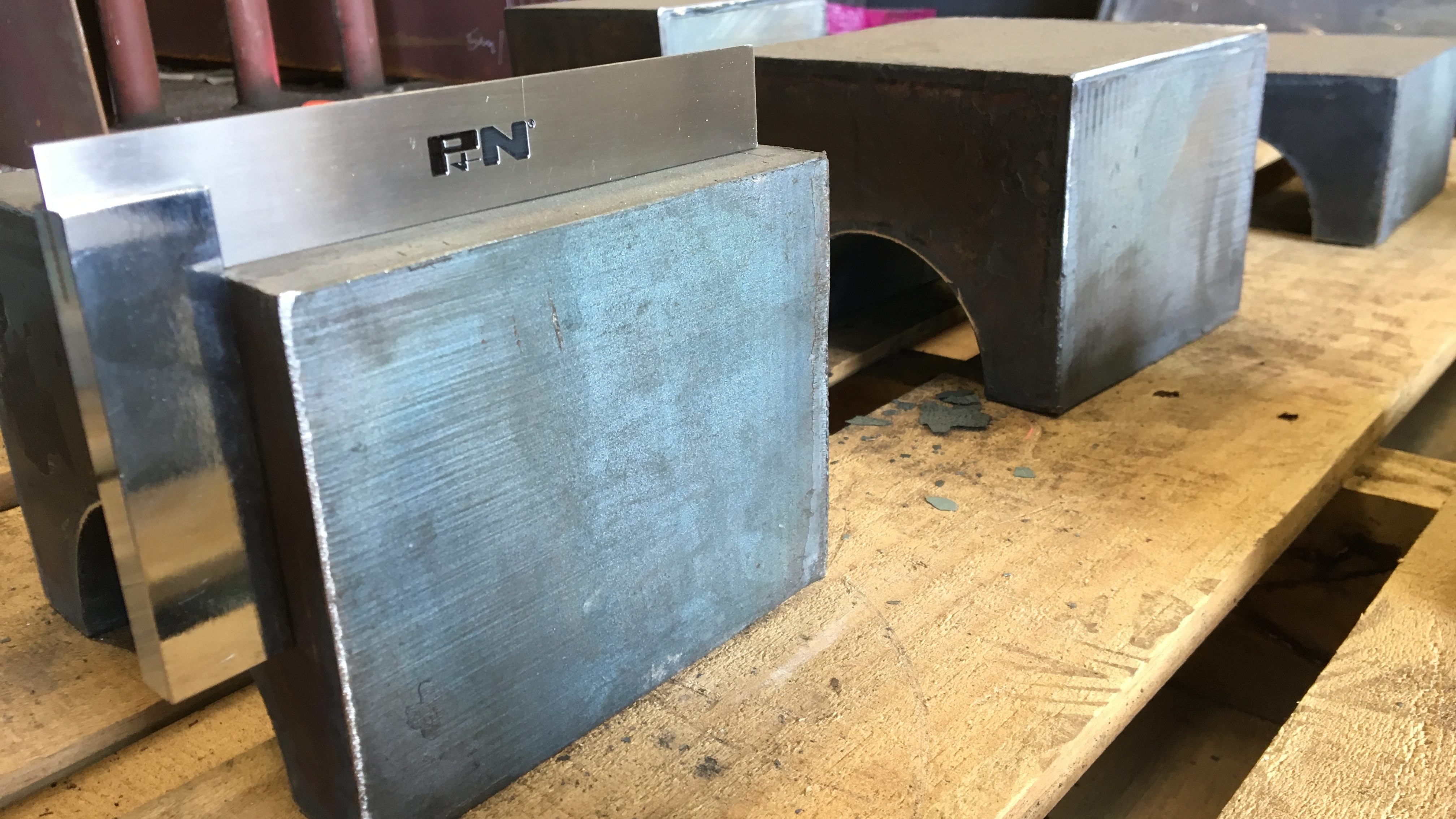

Square Gas Cuts

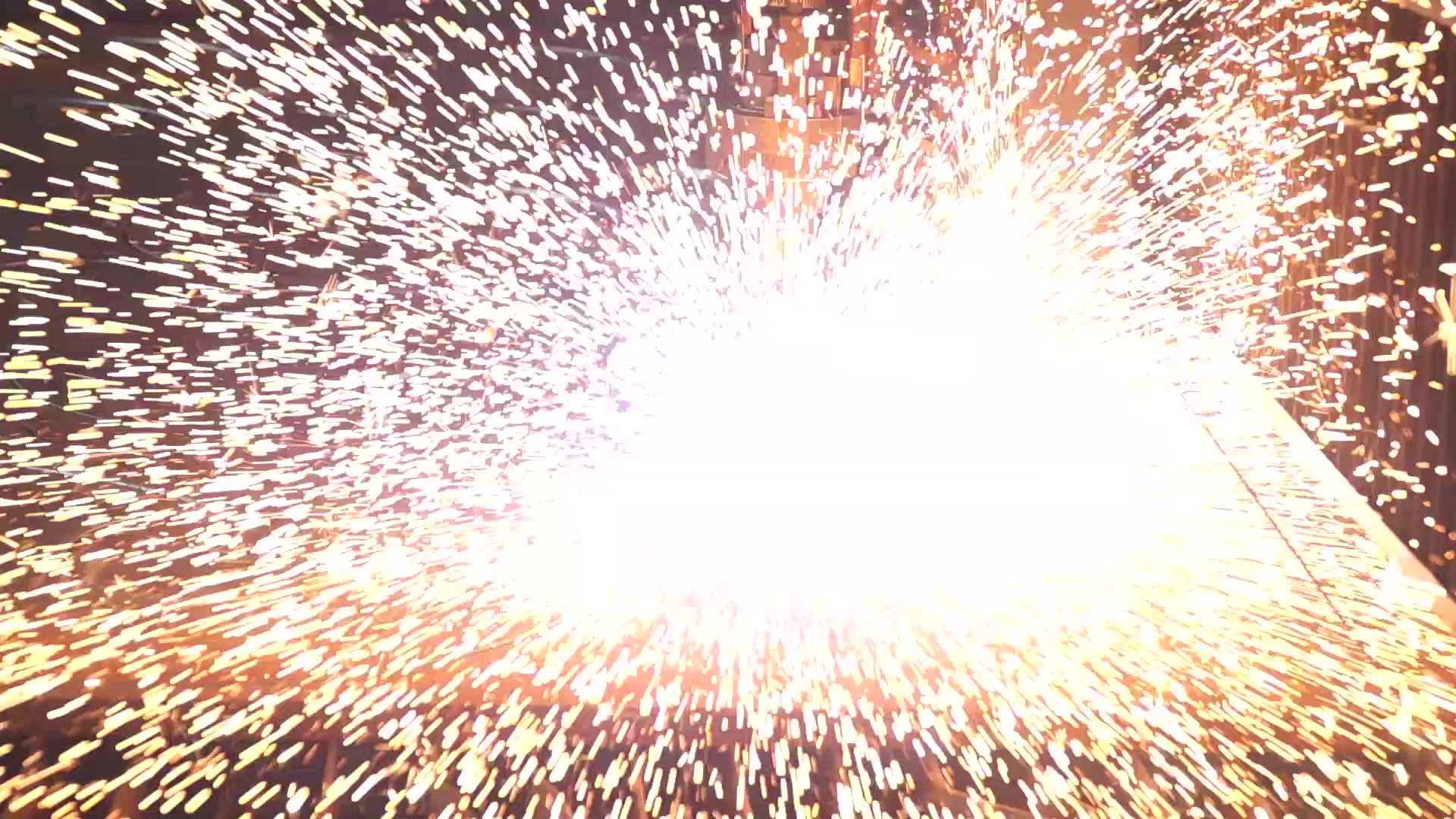

Multi-torch Cutting

Plasma Piercing

Looking for a Fast, Flexible and Reliable CNC Plate and Sheet Profiler? Talk to us today

Complete Plate Profiling Service

Fast

Service built around consistently providing the shortest lead times in the market and delivering express orders when our clients need it the most.

Flexible

Urgent orders, special projects or a unique challenge, we provide the agility and flexibility to respond to our clients unique demands on a person to person basis.

Reliable

We invest in systems, process and people with the one goal of providing reliability of service to our customers. We are dedicated to delivering on our promises.

One-Stop Shop

Laser, Plasma and Gas cutting and a full range of secondary processes to press, roll, machine, guillotine, weld and surface-treat your parts, in one order.